Since the 1970s, liposomes have been investigated as potential drug delivery systems because of their biocompatibility and ability to incorporate both hydrophilic and hydrophobic therapeutic agents. Drug delivery using liposomes has numerous benefits, particularly in reducing the risk of toxic side effects, a significant issue for chemotherapeutics which often exhibit high toxicity to healthy body organs and tissue.

Dr Christopher Shade, PhD has continued this research. After developing the patented liquid chromatographic mercury speciation technology, his current focus is on the development of cutting-edge, lipid-based delivery systems for nutraceuticals, such as liposomes and micro-emulsion systems to address the growing need of high quality, affordable detoxification solutions.

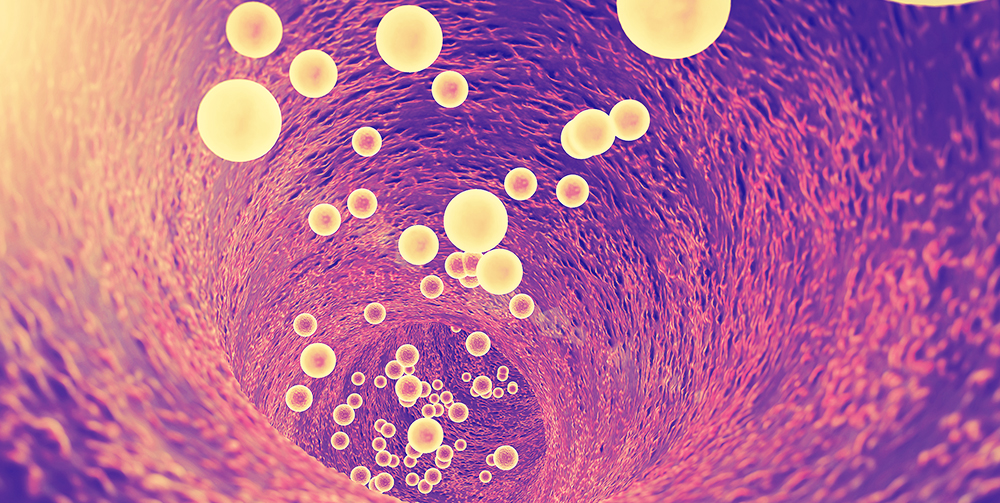

Liposomes are nano-sized vesicles with spherical, closed structures, composed of curved phospholipid bilayers that enclose part of the surrounding solvent/aqueous solution into their interior. The vesicle phospholipids are identical to the phospholipids that make up cell membranes. The structure of liposomes allows them to engulf biologically active substances that are readily absorbed and utilised by the body.

The polar head groups are located at the surface of the membranes, in contact with the medium, whereas the fatty acid chains form the hydrophobic core of the membranes, shielded from the water. Polar molecules can be encapsulated in the aqueous core, while hydrophobic molecules dissolve in the bilayers

of liposomes.

The inside of the liposome membrane is hydrophobic (water-hating), while the core of the vesicle is hydrophilic (water-loving). A significant advantage of liposomes is that they can incorporate and release two materials with different solubilities simultaneously. One example for which is the incorporation of two antioxidant agents namely cholecalciferol/vitamin D3 (a lipid-soluble molecule) and glutathione (a water-soluble molecule) in the same lipid vesicle.

Phospholipids are therapeutic in their own right (not just carriers) and the most beneficial of these is phosphatidylcholine (PC). PC is the main structural support of cell membranes and a micellising constituent of bile, which has been used extensively for regenerating and detoxifying the liver in fatty liver disease and hepatitis, clearing arterial plaque and repairing nerve damage.

Phospholipids have “heads” that mix well with the water inside and outside cells, and “tails” that mix with fats to form cell membranes. These properties make phospholipids ideal emulsifiers.

Most liposomes use crude soy lecithin, which is low in PC and does not have the therapeutic benefits. The material used in the formation of our liposomes is phosphatidylcholine, sourced from non-GMO lecithin in sunflower seeds.

How do liposomes work?

Liposomes are administered orally for transmucosal absorption in the mouth. Delivery efficiency is size-dependent with smallest sizes (<100nm) showing fastest absorption.

Liposomes, and other lipid particles, are cleared from the blood by the reticulo-endothelial system (RES), also called the mononuclear phagocyte system (MPS), a system of monocytes and macrophages in the liver and spleen that clear particles out of the blood.

Clearance is inversely related to size, with the small unilamelar lipsosomes (SUVs) circulating the blood the longest. Capture by the RES starts to decrease as sizes drop below 200nm and best evasion rates are below 125nm.

A good product must have a small mean diameter and a tight distribution of sizes. Even if the mean size of a products is small, products with a wide distribution of sizes have a large volume of the liposomes in non-ideal size ranges.

Further advances in liposome research have been able to allow liposomes to avoid detection by the body's immune system, specifically, the cells of the RES, thus protecting it from liver and spleen clearance and consequently prolonging its circulatory time. As a result of these studies, a kind of liposome so-called “stealth particles” has emerged. Stealth liposomes are made by covering the carrier surface with hydrophilic chains, such as polyethylene glycol (PEG).

PEGs increase the bioavailability of substances, keeps them stable, increases long circulation in the body and increases uptake through the blood-brain barrier. Otherwise known as tocophersolan, the PEG form we use is a water-soluble form of vitamin E (d-alpha tocopheryl polyethylene glycol 1000 succinate).

Tocophersolan coated liposomes are more stable in biological environments and can exhibit up to 10-fold higher circulation half-lives that liposomes without hydrophilic surface coatings.[1,2]

Types of liposomes depending on size and number of lamellae

Advantages of liposomal delivery

- High bioavailability and absorption compared to other oral forms of supplements, with 90% delivery rate compared to 20%.

- Non invasive; avoids pain and discomfort associated with injections and decreases the contamination risk.

- Nano-encapsulation protects against the harsh environment of the gastrointestinal tract and increases transmucosal (oral) uptake and absorption.

- Attach to cellular membranes and fuse with them, releasing their contents into the cell, bypassing the digestive processes that normally degrade or limit the compounds' absorption.

- Demonstrate the ability to cross the blood-brain barrier, deposit their cargo intracellularly and enhance lymphatic circulation of therapeutic compounds.

- Can complex both with negatively and positively charged molecules.

- Able to incorporate and release two materials with different solubilities simultaneously.

- Low gastrointestinal upset.

- Liposomal liquids are ideal for those for whom swallowing a tablet is not possible.

- Liposomal liquids allow for adjustable and incremental dosing for children and adults.

- Cost effective by being able to take a lower dose for the same effect.

The structure of liposomes allows them to engulf biologically active substances that are readily absorbed and utilised by the body.

How are liposomes made?

Liposomes can be created by mixing phosphatidylcholine-rich phospholipids in water. Low shear rates create multilamellar liposomes, which have many layers like an onion.

Traditionally, nutritional manufacturers have used low to medium shear methods, producing either gel-phase products (pasty and difficult to disperse) with very high diameter particles of a large range of size 400-1000nm, or, at best, milky liposomal solutions of 200-400nm, all of which have decreased oral and cellular uptake and increased clearance by the RES.

Small liposomes are the results of refined chemistry and high shear equipment. Small liposomes are drastically more efficient at intracellular delivery of encapsulated compounds.

In a recent study, with carefully-sized liposomes, cellular uptake increased 9-fold as liposome size was decreased from 236nm to 97nm and was 34-fold higher at 64nm. For some compounds, because of the concentration inside te liposome, delivery rates can be up to 500-fold those of free diffusion.[3]

References

- Klibanov AL, Maruyama K, Beckerleg AM, et al. Activity of amphipathic poly(ethylene glycol) 5000 to prolong the circulation time of liposomes depends on the liposome size and is unfavorable for immunoliposome binding to target. Biochim Biophys Acta 1991;1062(2):142-148. [Abstract]

- Allen TM, Hansen C, Martin F, et al. Liposomes containing synthetic lipid derivatives of poly(ethylene glycol) show prolonged circulation half-lives in vivo. Biochim Biophys Acta 1991;1066(1):29-36. [Abstract]

- Sharma A, Sharma US. Liposomes in drug delivery: progress and limitations. Intern J Pharmaceutics 1997;154(2):123-140. [Abstract]

DISCLAIMER:

The information provided on FX Medicine is for educational and informational purposes only. The information provided on this site is not, nor is it intended to be, a substitute for professional advice or care. Please seek the advice of a qualified health care professional in the event something you have read here raises questions or concerns regarding your health.